Upcoming EU regulations will also set new standards for the sustainability of electronics.

The foundation of the electronics industry needs to be rethought to make sustainable materials and processes the new normal – without compromising on performance.

The Finnish partners in the EU-funded Sustronics consortium include the VTT Technical Research Centre of Finland, Tampere University and six companies. VTT serves as the national coordinator. The partner companies are Canatu, Movesense, Screentec, Tervakoski, UpCode and UPM Raflatac. The Finnish partners receive part of their project funding from Business Finland. The entire Sustronics consortium comprises 46 partners from 11 countries.

The research project is funded by the EU (Horizon-KDT-JU-2022-2-RIA), national funding agencies and the project partners.

A key ambition of the Sustronics project is to lead the way in building an ecosystem for the electronics industry to address its sustainability challenges. The partners will carry out pilot projects to redesign existing electronic devices and create new ones.

Responsible electronics are based on environmentally friendly materials

The project participants from Tampere University are Matti Mäntysalo, a professor of electronics in the Faculty of Information Technology and Communication Sciences, and Ulla Saari, a senior research fellow in the Industrial Engineering and Management Unit at the Faculty of Management and Business. Saari’s area of expertise is the development and management of sustainable technologies and innovations.

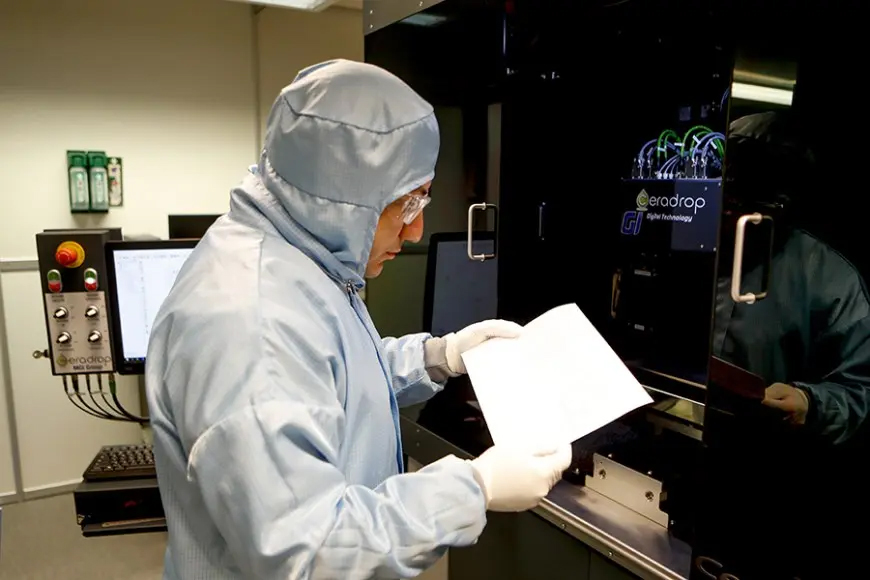

Mäntysalo’s research group studies new materials and manufacturing processes for electronics. In the Sustronics project, the researchers develop eco-friendly supercapacitors as an alternative to conventional batteries which contain rare raw materials that have a negative impact on the environment.

“We are developing next-generation energy storage technology to replace batteries in low-power sensor nodes. The supercapacitor is made from environmentally friendly, nontoxic materials,” Mäntysalo says.

As the market for wearable medical technology has experienced robust growth in recent years, there is an increasing need to develop wearables made from recycled and biobased materials.

“The currently available wearable devices have components derived from oil, so they are fossil-based. We are studying and conducting tests on alternative materials to shed light on their yet unknown properties.”

In addition, pilot projects will be carried out by the partner companies to develop environmentally friendly options for rapid at-home medical testing, among other things.

Circular business models for the electronics industry

Researchers in the Industrial Engineering and Management Unit are creating circular business models for the products developed during the pilot projects.

“The objective in the project is to utilise the results from the pilot projects’ lifecycle assessments to minimise the environmental impact of the products already in the early stages of the development of circular business models,” says Senior Research Fellow Ulla Saari.

The implementation of circular business models poses particular challenges for the electronics industry.

“For instance, repairability is not among the top priorities for consumer electronics manufacturers, recycling is not properly organised, and there are no clear guidelines or systems for the safe disposal of e-waste. We aim to develop circular business models that also address these issues. When the future reuse of materials and product parts is considered from the very beginning in the product design stage, companies will be able to shift to increasingly sustainable and environmentally friendly products and services.”

Headed by Philips, the project brings together research institutions, raw materials suppliers, manufacturers and e-waste recycling companies, among others. The EU-funded project aims to accelerate the transition not only towards sustainable materials, design and manufacturing but also towards greater circularity and energy efficiency in the electronics industry across Europe.

Sustronics is a collaborative effort involving 46 partners from 11 EU countries. The project has a total budget of €40 million.

Sustainable and green electronics for circular economy (SUSTRONICS)

The EU’s new Ecodesign for Sustainable Products Regulation, which sets out a framework of requirements to make products more sustainable throughout their lifecycle, will take effect in early 2024. As a result, manufacturers must demonstrate that all products sold in the EU meet the minimum requirements.

Sustronics was launched to help the electronics industry ensure compliance with the new requirements.

Read the news from VTT Technical Research Centre of Finland

Project description and partner on Tampere University website