Duration: 2022-2025

Programme: HORIZON.2.4 – Digital, Industry and Space

Topic: HORIZON-CL4-2022-TWIN-TRANSITION-01-04 – Intelligent work piece handling in a full production line (Made in Europe Partnership) (RIA)

Link: Click here

AGILEHAND is a groundbreaking project focused on revolutionizing workpiece handling systems. It aims to develop innovative solutions for three key aspects: fine grading of delicate and perishable products, seamless handling of diverse and deformable objects, and implementing agility, flexibility, and reconfigurability in production lines. By leveraging advanced technologies and AI-based systems, AGILEHAND ensures cost-effective, accurate, and fast grading, enables efficient handling of soft products, and facilitates agile production line reconfiguration for optimal customer response time and resource utilization. This project promises to enhance efficiency, accuracy, and productivity in manufacturing processes, setting new standards in the industry.

Objectives

EU manufacturers in the sector of Conveyor Systems and especially robots for automated material handling play an important role in growing global world market.

Many objects handled by those robots like food, clothes, bottles, or plastic items, are soft or deformable and they are not yet efficient and effective in handling these objects.

In this context, AGILEHAND aims at developing advanced technologies for grading, handling and packaging autonomously soft and deformable products, as a strategic instrument to improve flexibility, agility and reconfigurability of production and logistic systems of the European manufacturing companies.

Impact

- Developing highly Flexible, Resilient, Reconfigurable and Agile production lines able to handle a variety of different product with high precision:

- To develop a Smart sensing system that can scan and fuse data from interior and exterior scans of different products,

- To develop an AI product grading system that can generate more precise results for product handling,

- To develop a Smart manipulator system that can Pick-Up and Re-Orientated Different Soft and Deformable Products without causing product damage,

- To develop a Smart conveyance system that can Move Different Delicate Products, Independently of each other.

- Deploying easy to program advanced control systems capable of intelligent handling of complex products in terms of shape, size, material and stiffness:

- To develop AI solutions that can ‘suggest/recommend’ the best setup/line-configuration,

- To enhance Control systems for production and logistic synchronization,

- Increasing productivity by enabling fast and accurate movement of work pieces through the production line, ensuring just-in-time delivery and reducing downtime:

- To develop a Smart Sensing network re-calibration system that can facilitate fast-reconfigurations for new products or layouts,

- To develop an AI based solutions to predict and optimize system performance, ensuring the robustness of production programmes and considering collaborative (human-in-the-middle) approaches,

- To develop an Adaptive handling and moving system that reacts to product quality.

Role of FAST-Lab.

FAST-Lab. is the leader of the work package for Self-Adapting Handling, Sorting and Packaging.

- FAST-Lab. is the leader of three tasks in the suite:

- T5.1: Smart transportation technologies for soft and deformable products

- T5.2: Intelligent manipulators and self-adaptation for soft and deformable products

- T5.4: Robot-Robot collaboration for soft and deformable products

- FAST-Lab. is the vice-leader of two tasks:

- T4.2: Grading Internal and External Product Quality

- T6.2: Data-Driven Digital Twin for Production and Logistic System Synchronization

-

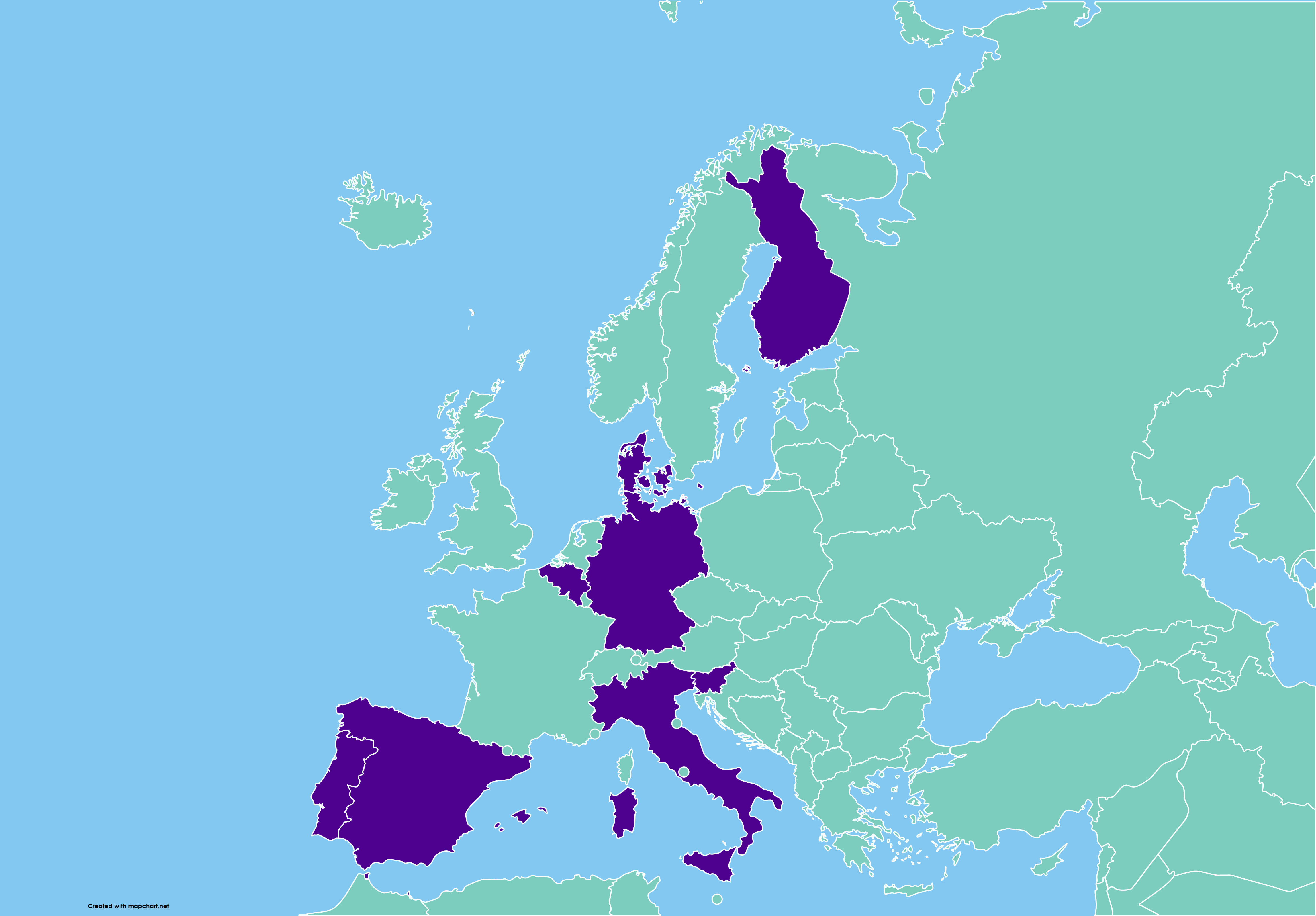

- TAMPEREEN KORKEAKOULUSAATIO SR: FAST-Lab.

- UNIVERSITAT POLITECNICA DE VALENCIA: SPAIN

- MULTISCAN TECHNOLOGIES SL: SPAIN

- AINIA CENTRO TECHNOLOGICO: SPAIN

- FONDAZIONE BRUNO KESSLER: ITALY

- B2A: ITALY

- SANT ORSOLA SOCIETA COOPERATIVA AGRICOLA: ITALY

- UNINFO: ITALY

- KNOWLEDGEBIZ: PORTUGAL

- UNINOVA-INSTITUTO DE DESENVOLVIMENTO DE NOVAS TECNOLOGIAS-ASSOCIACAO: PORTUGAL

- FACTOR SOCIAL – CONSULTORIA EM PSICO – SOCIOLOGIA E AMBIENTE LDA: PORTUGAL

- PRODUMAR – PRODUTOS DO MAR: PORTUGAL

- ASSOCIACÄO PORTUGUESA PARA A QUALIDADE: PORTUGAL

- FRAUNHOFER GESELLSCHAFT ZUR FORDERUNG DER ANGEWANDTEN FORSCHUNG EV: GERMANY

- FLANDERS’ FOOD BRUSSEL: BELGIUM

- LABORATOIRE VIRTUEL EUROPEEN DANS LE DOMAINE DE L’INTEROPERABILITE DESENTREPRISES: BELGIUM

- MARELEC FOOD TECHNOLOGIES NV: BELGIUM

- FUNDINGBOX RESEARCH APS: DENMARK

- FUNDINBOX COMMUNITIES SL: SPAIN (3RD PARTY)

- TOKYO UNIVERSITY TECHNOLOGY: JAPAN (ASSOCIATED PARTNER)

- NAGASAKI UNIVERSITY: JAPAN (ASSOCIATED PARTNER)

Coordinator: UNIVERSITA POLITECNICA DELLE MARCHE: ITALY

Participant Organizations:

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No. 101092043. Neither the European Commission(EC) or any person acting on behalf of the commission is responsible for how the following information used. The views expressed in this publication are the sole responsibility of the authors and do not necessarily reflect the views of the EC.