Duration: 2022-2025

Programme: HORIZON EUROPE – Digital, Industry and Space

Topic: HORIZON-CL4-2021-TWIN-TRANSITION-01-01 – AI-enhanced robotics systems for smart manufacturing (AI, Data and Robotics – Made in Europe Partnerships) (IA)

Link: Click here

AI-PRISM is an industry-driven initiative aimed at delivering a comprehensive ecosystem of AI-based solutions tailored to manufacturing scenarios characterized by challenging automation requirements and the need for rapid adaptability. The project’s primary objective is to provide a human-centric framework that enhances manufacturing capabilities by enabling semi-automated and collaborative processes in flexible production environments. Notably, AI-PRISM eliminates the necessity for specialized robotic programming skills through the utilization of programming-by-demonstration modules. The outcome of this undertaking will be an integrated and scalable ecosystem featuring customized solutions designed to meet the specific needs of individual installations within the manufacturing sector.

Objectives

-

- To develop a shared project vision, aligned with the state-of-the-art technological landscape in collaborative robotics, artificial intelligence, and cloud computing applied to smart manufacturing with a focus on manufacturing flexibility and resilience.

- To develop a technical and methodological framework common to all development activities and create a reference architecture, delivering technical and functional specifications through a user-centric approach.

- To build the AI-PRISM Human Centred Collaborative Platform, integrating a ROS-based robotic platform able to digitalize the collaboration environment (including humans) and interact with it thanks to real-time communication networks and services, and programming by demonstration modules.

- To build the AI-PRISM AI Enhancing toolset, a set of AI-based tools to enhance the reasoning, perception, and coordination abilities of the system, enabling collaboration with humans in complex environments, supported by a continuous integration and validation establishment to maximise development performance.

- To build a solid scientific base rooted in social sciences to guide the design and implementation of AI-PRISM solutions, and to demonstrate qualitatively and quantitatively the impact of AI-PRISM solutions.

- To demonstrate the results of the project in 4 user pilots, involving different industrial sectors, types of robots and industrial processes that are difficult to automate, plus a generic demonstrator.

- To build a network of open access pilots that engages academic and industrial actors, using the built-in AI-PRISM simulation services to empower demonstration, training, certification, and development activities.

- To disseminate the results of the project, and to liaise with relevant standardisation activities to promote the rapid adoption of AI-PRISM solutions by the manufacturing industry.

- To implement effective project management practices to ensure the completion of the project objectives according to the established project plan.

The ecosystem will be composed of four main pillars;

- 1) Human Centred Collaborative Robotic Platform

- 2) Human-Robot Cooperation Ambient

- 3) Social Human-Agent-Robots Teams Collaboration

- 4) Open Access Network Portal

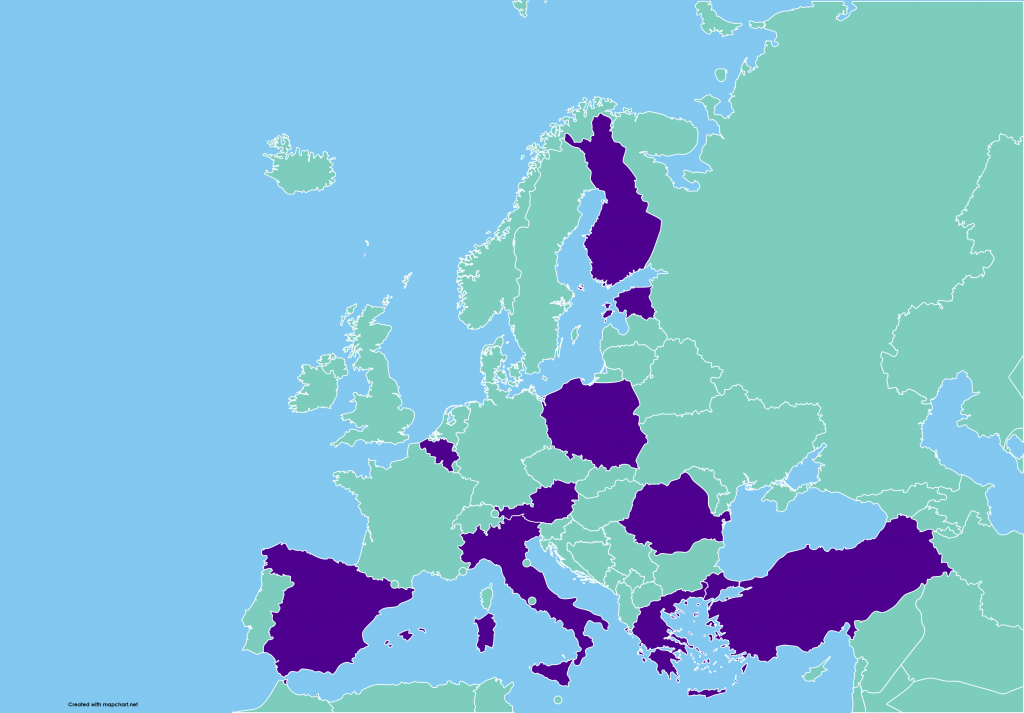

In order to facilitate the assessment of the performance, transferability, scalability and large-scale deployment of these solutions, the demonstrations will be conducted under real operational environments in four pilots involving key manufacturing sectors – Furniture (ES), Food/Beverage (GR), Built-in Appliances (TR) and Electronics (PL), and one generic demonstration facility (AT).

Impact

-

- AI-PRISM will create a basic level of awareness of HRC and AI tools among over 10,000 EU manufacturing SMEs by 2030, with 30% implementing any of these advanced technologies.

- Highly efficient systems and digital twins will represent a net mitigation potential of 30% in industrial electricity use and 50-60% in CO2 emissions.

- AI-PRISM will enter the ‘Production’ stage by 2030 reaching TRL 8, and Gross ROI will be 150% in ten years.

- Compliant technology vendors will obtain 10% higher sales.

- Big enterprises will report 10+% in costs reductions and 5+% in increased revenues; SMEs will report 40+% in costs reductions and 25+% in increased revenues.

- AI-PRISM will attain an ‘SRL 8: Solution and societal adaptation completed’; 10% up-skilled workforce; 10+ new job profiles

- Fatal work injuries will be reduced 20%; 40% in highly constrained spaces.

- 15% increase in new jobs filled by young workers

The primary objective of the project extends beyond achieving mere quantitative advancements within a specific sector. Instead, it strives to leverage technological innovation as a catalyst for a paradigm shift in the manufacturing domain, where the integration of AI, robotics, and Social Sciences and Humanities (SSH) plays a pivotal role. The ultimate aim is to enhance flexible production processes and establish them as viable and widely adopted alternatives for European factories, particularly Small and Medium-sized Enterprises (SMEs). By intertwining these diverse disciplines, the project seeks to revolutionize manufacturing practices, fostering improved efficiency, adaptability, and overall operational performance across the industry.

Role of FAST-Lab.

- Develop models of the user experience of the main stakeholders (production engineers, operators, integrators) interacting with AI-PRISM technologies.

- Development of a Collaborative Simulation Platform, that will enable the design and simulation of specific production plants or lines, including the interaction between existing agents will be developed. On the one hand, industrial machinery and production environment will be simulated using already existing simulation software (Gazebo, Issac Sim, CoppeliaSim…). On the other hand, robotics. agents will be integrated by their URDF models while a new human agents’ simulator will be developed and integrated with the environment simulator software. These modules will collaborate with other modules developed during the project such as behavioural models, human intention or safety risk assessments modules that will be used to evaluate the collaboration and for risk analysis.

- Demonstrating the AI-PRISM approach of establishing the AI-PRISM alliance of open-access pilots (OAPs). The OAPs would provide a simulation platform for end users, to utilize facilities, equipment, manipulators, etc. of an organization (established within the alliance) remotely; And the AI-PRISM software suite would facilitate this platform. Additionally, the suit would also have provisions for an interactive training engine and supports a scheduling and optimization engine.

To accomplish its ambitious goals, the project relies on the collective efforts of a robust consortium consisting of 25 partners from 12 countries. Furthermore, the project also involves international collaboration with Korea, adding a global perspective and expertise to the initiative. The consortium is carefully composed to encompass all key stakeholders within the Human-Robot Collaboration (HRC) value chain. This includes relevant competence centers, technology providers, equipment suppliers, system integrators, as well as manufacturers and end-users. In addition to the technical expertise, the project incorporates the valuable insights and contributions of esteemed partners specializing in Social Sciences and Humanities (SSH), standardization, exploitation, and dissemination. By bringing together these diverse actors, the project ensures comprehensive coverage of all relevant domains, fostering a holistic approach towards achieving its objectives.

Coordinator: NTT DATA SPAIN, SL; SPAIN

Participant Organizations:

-

- TAMPEREEN KORKEAKOULUSAATIO SR: FAST-Lab.

- UNIVERSITAT POLITECNICA DE VALENCIA: SPAIN

- IKERLAN S. COOP: SPAIN

- INSTITUTO TECNOLOGICO DE INFORMATICA: SPAIN

- ROBOTNIK AUTOMATION SLL: SPAIN

- ASOCIACION ESPANOLA DE NORMALIZACION: SPAIN

- ANDREU WORLD DESIGN SA: SPAIN

- FONDAZIONE BRUNO KESSLER: ITALY

- COMAU SPA: ITALY

- KATHOLIEKE UNIVERSITEIT LEUVEN: BELGIUM

- MTU AUSTRALO ALPHA LAB: ESTONIA

- TEKNOPAR ENDUSTRIYEL OTOMASYON SANAYI VE TICARET ANONIM SIRKETI: TURKIYE

- SILVERLINE ENDUSTRI VE TICARET A.S.: TURKIYE

- SIEC BADAWCZA LUKASIEWICZ – PRZEMYSLOWY INSTYTUT AUTOMATYKI I POMIAROW PIAP: POLAND

- VIGO PHOTONICS SPOLKA AKCYJNA: POLAND

- WINGS ICT SOLUTIONS INFORMATION & COMMUNICATION TECHNOLOGIES IKE: GREECE

- ATHINAIIKI ZYTHOPIIA ANONYMOS ETAIRIA: GREECE

- PROFACTOR GMBH: AUSTRIA

- KEBA GROUP AG: AUSTRIA

- NTT DATA ROMANIA SA: ROMANIA

- ASOCIATIA TRANSILVANIA IT: ROMANIA

- EVERIS ITALIA SPA: ITALY (3RD PARTY)

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement No 101058589. Neither the European Commission(EC) or any person acting on behalf of the commission is responsible for how the following information used. The views expressed in this publication are the sole responsibility of the authors and do not necessarily reflect the views of the EC.