Duration: 2019-2023

Programme: H2020-EU.2.1.5. – INDUSTRIAL LEADERSHIP – Leadership in enabling and industrial technologies – Advanced manufacturing and processing

Topic: DT-FOF-12-2019 – Handling systems for flexible materials (RIA)

Link: Click here

REMODEL (Robotic technologies for the manipulation of complex deformable linear objects) project is a four-year project funded by the European Commission in the Horizon 2020 programme. The project consortium involves eleven partners.

Objectives

-

- Manipulation devices and robotic platforms specialized for the manipulation of DLOs

- 3D environment reconstruction, part identification, localization and deformation tracking

- Modelling, identification, prediction and tracking of DLO shape and behaviour

- Control algorithms based on perception data and DLO models, to join task planning and feedback control

- DLOs grasp and manipulation control by vision-tactile-proximity data fusion, to manipulate DLOs in partially structured environments

- Exploring Interactive Perception paradigm, to enrich sensory data with action to make perception robust

- Motion planning in cluttered environments and the manipulation of complex DLOs composed by multiple branches

- Automated task planning to generate task sequence for the robots automatically from digital product design

- Teaching by demonstration and tutored learning of robot skills, for new assembly references and tasks

REMODEL will enable new production environments, where the manufacturing of complex products composed of multiple wires and cables by means of robots is not only possible but fully integrated with the product design chain. Wires, cables, wiring harnesses, laces and flexible tubes have a transversal application in many manufacturing processes, where these technologies could lean the scale for total automation, decreasing production costs and improving worker conditions.

Impact

-

- Demonstrating the potential to bring back production to Europe

- 15% increase in OECD Job Quality Index through the work environment and safety improvement

- 20% increase in productivity

REMODEL will bring new opportunities to human-intensive labor manufacturing processes like the one dealing with cables and wires, where the routing and fitting tasks are calling for advanced handling techniques. The REMODEL robotic ability will impact several production scenarios in which human work is widely adopted due to the complexity of the objects, materials, and manipulation tasks, characterized by unpredictable initial configuration as well as large deformability and plasticity.To prove the effectiveness of the REMODEL outcomes, four industrial manufacturing use cases were provided by the industrial partners and covering five different domains, i.e. the production and assembly of wiring harnesses in the automotive and the aerospace field, the switchgear wiring and the manufacturing of medical consumables will be developed.

Role of FAST-Lab.

-

- Performing all the Work Package and Task level activities and meeting the set deadlines of Deliverables.

- Communicating with designated use case providers (ELVEZ, Slovenia) to get inputs and feedback for implementing the system for their application.

- Designing and setting up the physical robot platform for the ELVEZ use case in the laboratory.

- Working on creating a standardized ROS (Robot Operating System, a robotics middleware) based CAD platform interface, common for all the use cases. Where-in the component information, system information, routing information, sequence information, etc., for the individual use cases, are made accessible to the ROS-based Planner module of the system.

- Working on creating a standardized web-based user interface to visualize and manipulate the most relevant system and process information, required by the consortium members.

- Ideating and implementing standardized (and one specialized) safety systems for all the use cases. Additionally, creating a ROS-based controller to add redundancy and integrate with the ROS-based system.

- Developing a vision module for identifying individual cables for performing the cable separation with the robot and evaluating if the correct group of cables was grasped

- Developing a Teaching by Demonstration module for the workers, wherein they are capable of programming the tasks to be performed by the robot by demonstrating the assembly process and training the robot to reach maximum proficiency which would theoretically exceed the performance of the human worker, over time.

- Designing and prototyping a specialized spot taping gun as End-of-Arm-Tool, which is currently mounted and used by a dual-arm industrial robot, for the ELVEZ use case.

FAST-Lab. is the primary research partner focusing on the use case ‘Assembly of cable harness in the Automotive industry for the industrial partner ELVEZ, Slovenia. In addition to this, FAST-Lab. is also working on various elements of the other use cases. It is in charge of the ‘System and User Interface’ Work Package (each Work Package consists of multiple tasks) and the leader of 4 individual tasks across 3 different Work Packages

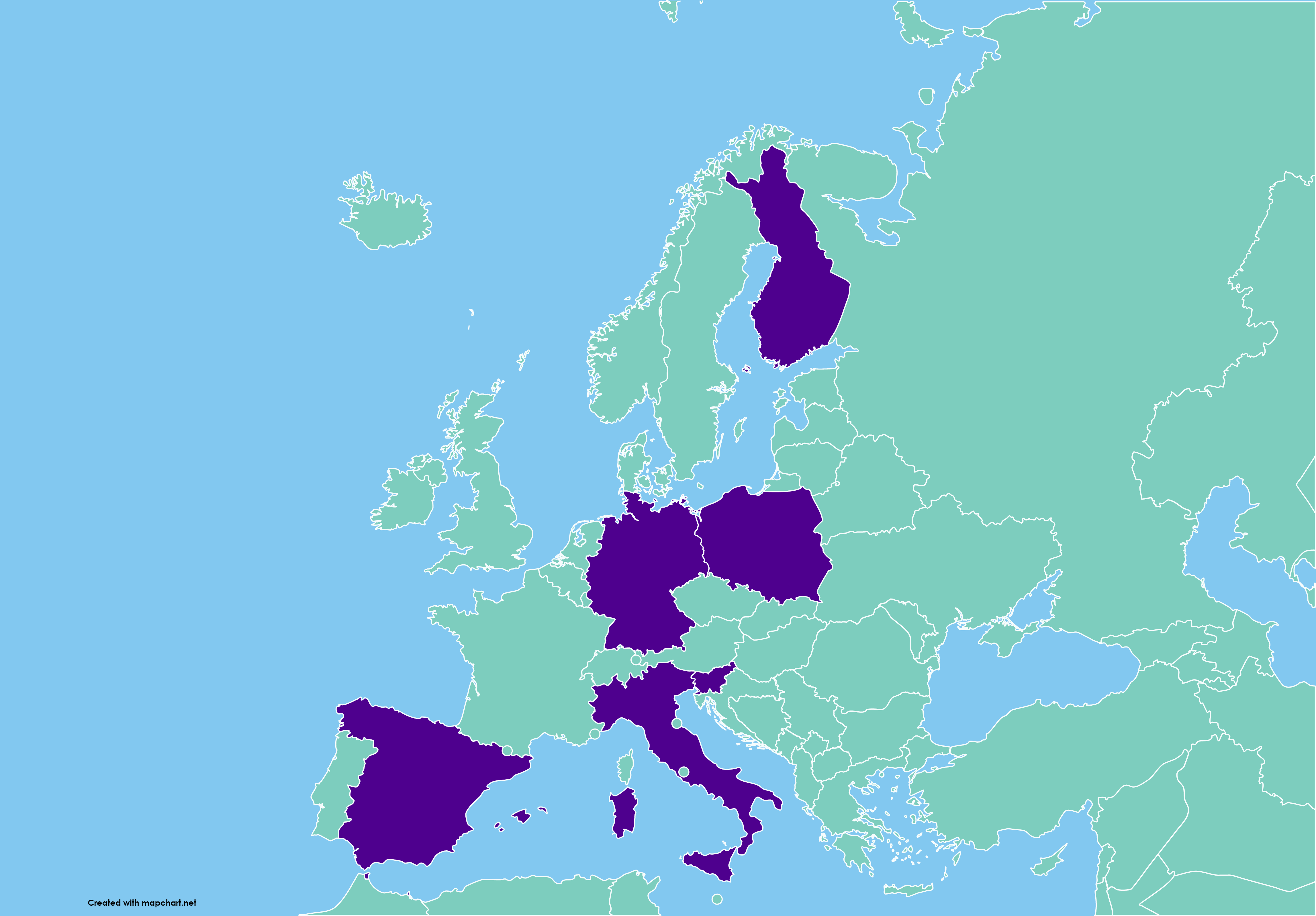

Coordinator: ALMA MATER STUDIORUM – UNIVERSITA DI BOLOGNA; ITALY

Participant Organizations:

- TAMPEREEN KORKEAKOULUSAATIO SR: FAST-Lab.

- UNIVERSITA DEGLI STUDI DELLA CAMPANIA LUIGI VANVITELLI: ITALY

- I.E.M.A. SRL: ITALY

- ENKI S.R.L: ITALY

- FUNDACION TECNALIA RESEARCH & INNOVATION: SPAIN

- ELIMCO AEROSPACE SL: SPAIN

- TECHNISCHE UNIVERSITAET MUENCHEN: GERMANY

- POLITECHNIKA POZNANSKA: POLAND

- VOLKSWAGEN POZNAN SP Z O.O.: POLAND

- ELVEZ, PROIZVODNJA KABELSKE KONFEKCIJE IN PREDELAVA PLASTICNIH MAS DOO: SLOVENIA

This project has received funding from the European Union\s Horizon 2020 research and innovation programme under the grant agreement No 870133. Neither the European Commission(EC) or any person acting on behalf of the commission is responsible for how the following information used. The views expressed in this publication are the sole responsibility of the authors and do not necessarily reflect the views of the EC.