Manufacturing ICT

Digitalization has many aspects. We go from concepts to communication and applications and beyond to role-based User Interfaces.

Reconfiguration of the manufacturing systems based on capabilities from H2020-ReCAM

The ReCaM approach towards the design and reconfiguration of production system is grounded on a capability-based system configuration method that considers mechatronic objects and the adaptation of their capabilities based on workpiece requirements. This approach facilitates the automatic matching between workpiece requirements and resource capabilities, and provides the basis for the auto-programming of the mechatronic objects for required tasks.

Resource models: http://resourcedescription.tut.fi/

LeanMES -

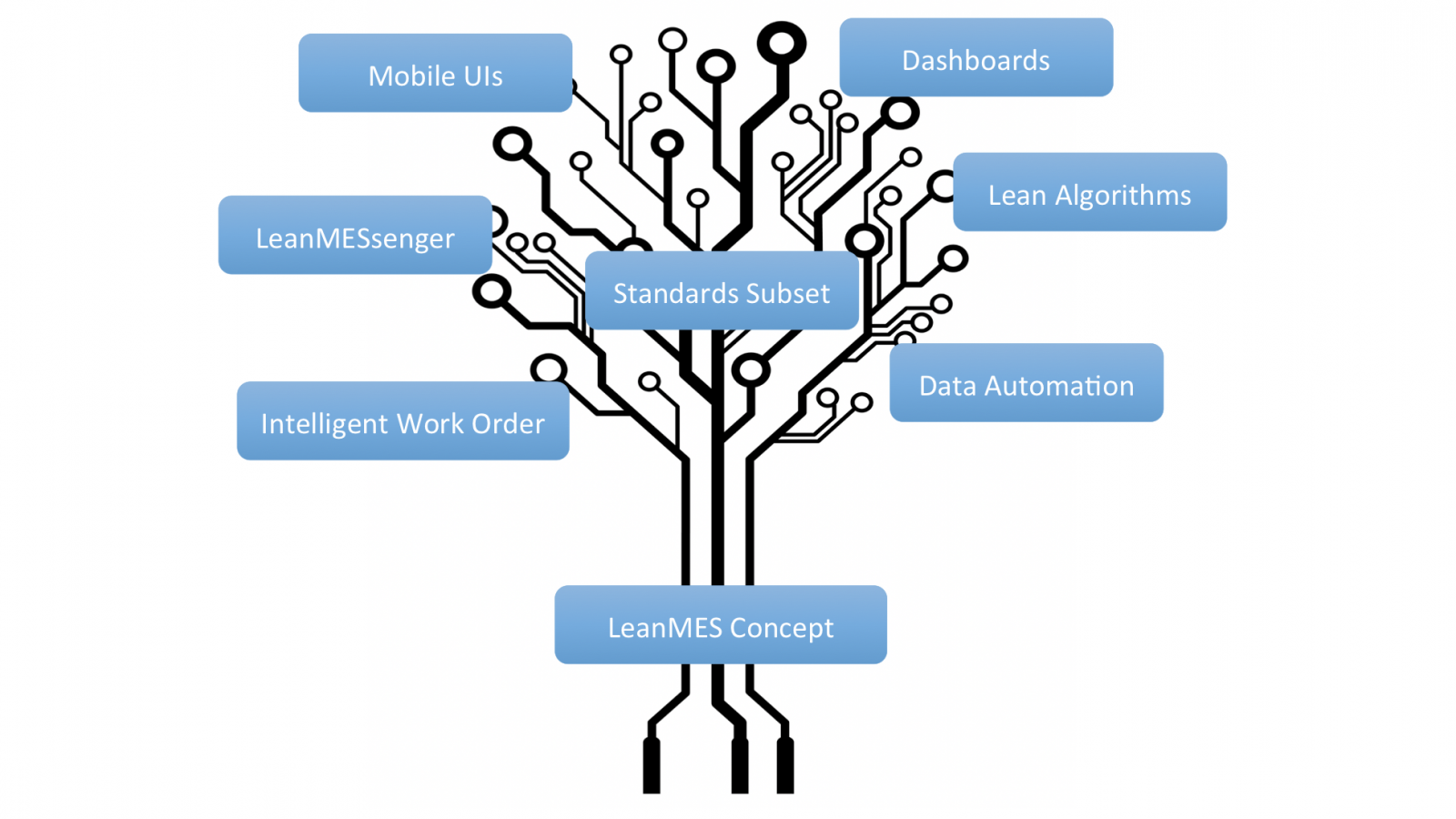

The ultimate goal of the LeanMES project was to provide lean, scalable and extendable concept for new type of MES that supports the human operator in a dynamically changing environment. This objective is reached by combining best of soft methods and hard technology.

LeanMES created a novel MES concept for networked SMEs that allowed them to observe, plan and react better in dynamic production environment. LeanMES concept utilized the skills and knowledge of the operator, and supported him/her via adaptive and intuitive interfaces to work in his/her daily shop floor level operations. The LeanMES approach differs from previous concepts by integrating the all three levels – machine, system and network – under one scalable concept, which supports human operators and provides open and standardized interfaces to other IT-systems.