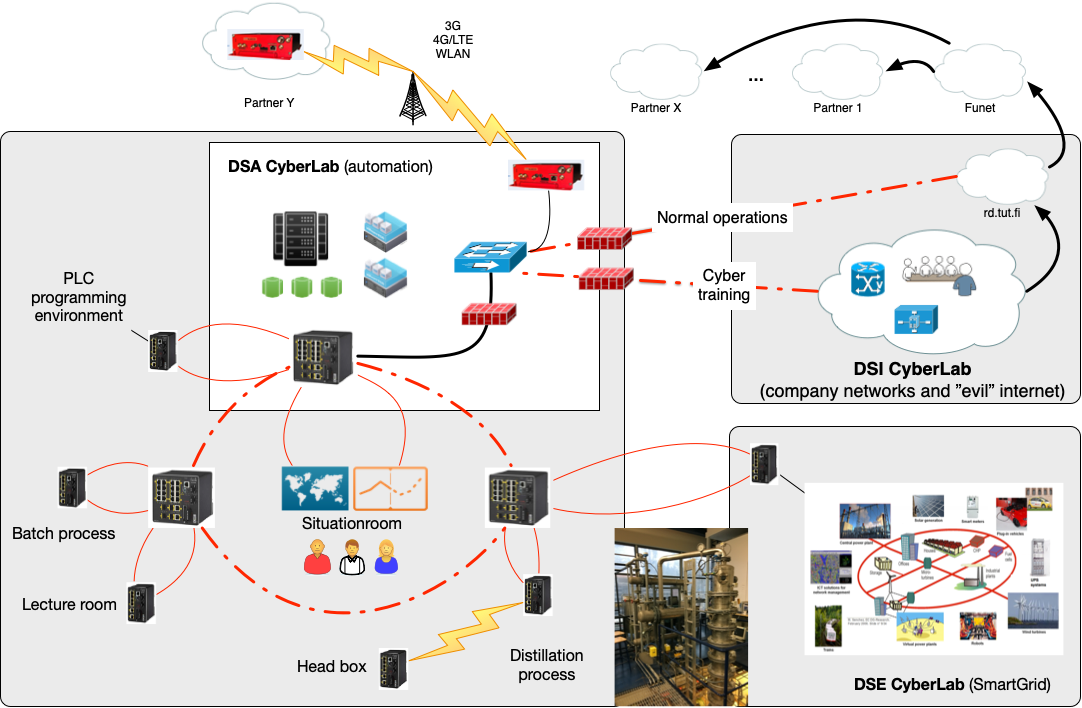

The infrastructure of the DSACyberLab provides modern industrial control system network interconnecting various processes from moving machines to process automation and Smart Grids. It is built from long lifecycle viewpoint. The main process is 45 years old and process equipment consists of components with different phases of lifecycle. The core automation system is kept as close to state-of-the-art as possible e.g. we have virtualised all non-realtime parts of the system.

The core network is industrial grade fiberoptic ring network built using modern industrial infrastructure components. It supports fast fault tolerance against cable problems and standard industrial communication protocols as well as modern mWave 5G communication. Many research and education environments utilize the core network and most important is the Distillation Process.

The core computing infrastructure is built on top of enterprise grade virtualisation solution adapted to automation environments. However, we still have capability to access serial port equipment and devices.

Use cases

- Control System Cyber Security Training for companies and their partners with customised content from automation basics all the way to incident response in Industrial Control Systems environment. Over 210+ participants from 30+ companies since 2010. (curriculum is in Finnish).

- Advanced research on Critical Infrastructure Protection whether it is related to electricity, everyday goods, medical environments, process automation, smart cities, transportation or moving machines. We started automation security research in 1999 and security mindset is built-in into all our projects.

- Basic and advanced education on information technologies in automation. We integrated cyber security to our curriculum 2005. All our graduate students have learned the importance of security in building and designing more dependable automation.

- Co-operation with companies on evaluating, testing and hackfesting critical equipment.

Contact

- Jari Seppälä, automation security generalist

- Mikko Salmenperä, automation security specialist

- Matti Vilkko, professor

- Hamed Badihi, assistant professor, Automation Technology and Dependable Systems