Another method to fabricate transparent low noise microelectrodes published

Thanks to the wisely chosen materials, the biologists can now both see and hear the cells properly in the electrophysiological experiments performed by our novel transparent microelectrode arrays (MEAs). The results of the multidisciplinary study, Transparent Microelectrode Arrays Fabricated by Ion Beam Assisted Deposition for Neuronal Cell in Vitro Recordings, by professor Pasi Kallio’s Micro- and Nanosystems Research group and adj. prof. Susanna Narkilahti’s NeuroGroup was published 14.5.2020 by MDPI Micromachines journal in its special issue Microelectrode Arrays and Application to Medical Devices.

Traditionally, microelectrodes used for recording signals from neuronal or cardiac cells have been either opaque with high signal-to-noise ratio (SNR) or transparent with high noise level. The former has been good if the researcher has been mainly interested in the recorded data, i.e., “hearing” the cells and the latter has been favored by the researchers whose preference is to observe the cells with an inverted microscope, i.e., seeing the cells. In many experiments, it would, however, be beneficial if the MEA had both high SNR and good visibility. An answer to this request was provided in MEA Meeting 2018 conference, where the idea of combining the low noise properties of columnar titanium nitride (TiN) and the (partial) transparency provided by the very low thin film thickness was suggested separately by us in co-operation with VTT and by the researchers from NMI/University of Tübingen. At that time, we used atomic layer deposition (ALD) and NMI used sputtering to deposit the thin TiN microelectrodes. However, both of these deposition methods share high source material costs and limited lift-off process compatibility, which makes the manufacturing challenging. Also, despite being rather common techniques, not everybody has access to those processes. So, for this study we decided to investigate, if another technique, ion beam assisted e-beam deposition (IBAD) could do the job as well.

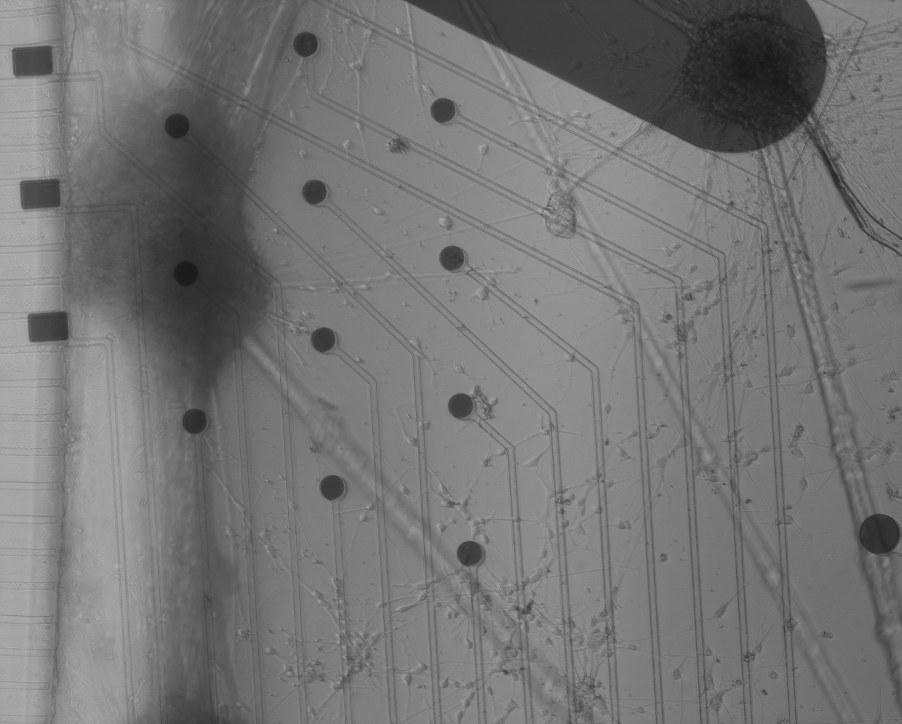

In the IBAD method, titanium is evaporated with traditional e-beam evaporation technique in a vacuum and is complemented by simultaneous nitrogen ion bombardment from an ion source to generate TiN. The same applies also to another transparent material indium tin oxide, ITO, which was used as the conductor material in this study. In the case of ITO, oxygen ions were used instead of nitrogen ions, of course. Our experiments proved that IBAD is a valid alternative for depositing both thin partially transparent TiN layers and almost fully transparent indium tin oxide (ITO) thin films. The benefits of IBAD method include low raw material and device investment costs and better lift-off compatibility compared with ALD or sputtering. The impedances and noise level of our IBAD ITO/TiN MEAs were in the same range as has been reported for corresponding MEAs fabricated with other methods. The seven weeks neuronal cell culture indicated also that the MEAs were biocompatible.

In many electrical devices, one concern is how the conductivity of the wires that connect different components affect the performance of the device. This was another research question that we investigated in this study. While testing different ITO thicknesses and qualities, we noticed that the double layer interface between the electrodes and the cells seems to dominate the MEA electrode impedance so strongly that it does not matter hardly at all how conductive the wires, i.e., the tracks that connect the electrodes to the contact pads in MEAs are – only the electrode surface material and its properties matter. This means that one does not need to search for the best possible conductivity for the tracks e.g., by using thick layers of expensive gold, but instead, one can safely choose a cheaper and less conductive track material and also use lower track thicknesses. This is an excellent news for our advanced disease model and body-on-chip development where we attach microfluidic silicone chips on MEAs. Thinner tracks would improve the smoothness of the MEA surface and would significantly help to reduce the leakage risks, which has sometimes been a problem with thicker tracks.

The research was funded by the Academy of Finland (CoEBoC and MEMO).

Ryynänen, T.; Mzezewa, R.; Meriläinen, E.; Hyvärinen, T.; Lekkala, J.; Narkilahti, S.; Kallio, P. Transparent Microelectrode Arrays Fabricated by Ion Beam Assisted Deposition for Neuronal Cell in Vitro Recordings. Micromachines 2020, 11, 497.