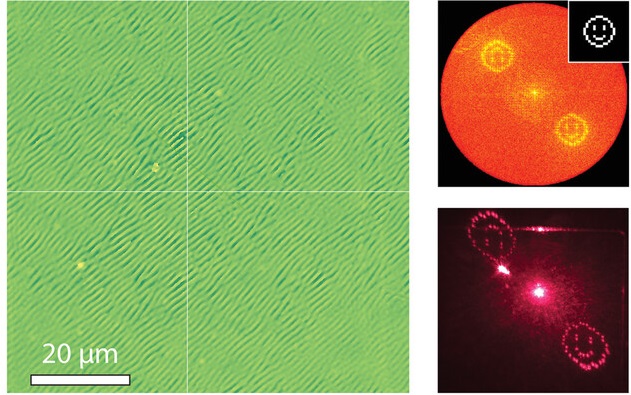

Using holographic lithography in combination with digital holographic microscopy we created the superposition of up to 80 surface relief gratings (SRGs) with high accuracy and minimal information loss in subsequent inscriptions.

This research demonstrates the capabilities of the modified digital holographic microscope in producing complex diffractive optical elements on azobenzene-based materials. The method allows for precise manipulation of grating parameters, including period, orientation, and height, which is essential for creating complex surface structures required in photonic applications such as near-eye displays, telecommunications, plasmonic sensors, and anti-counterfeiting measures. Superimposing a large number of gratings leads to new applications that require arbitrary and precise diffraction control. This represents a significant advance in the capabilities of photolithographic techniques based on azobenzene-based materials, offering a potential competitive advantage for this organic, reconfigurable material compared to existing photolithographic techniques.

adom202301597-sup-0002-movies2

The research was published recently in Advanced Optical Materials journal.