Digital Image Correlation (DIC) is a powerful tool for analyzing deformation of an object. It is based on comparing optical images obtained from a moving and/or deforming object. The comparison of the images allows obtaining displacement vectors of the surface of the image at a very high spatial resolution. If two or more cameras are used, also the out of plane displacements can be obtained. DIC can be compared to as having thousands of mini-extensometers on the sample. The benefits of DIC include:

- Non contact, non intrusive

- Full field data (thousands of mini extensometers) and extraction of e.g. strain plots along a 1D line

- System is not damaged when sample fails

- Suitable in harsh environments (chambers)

- Possible to use where specimen is submerged in solution

- Identify strain hot spots over a larger area

- Visualization of results and easy comparison with FEM simulations

- Do not need to know where to place the gauge / extensometer before the test

How does it work…?

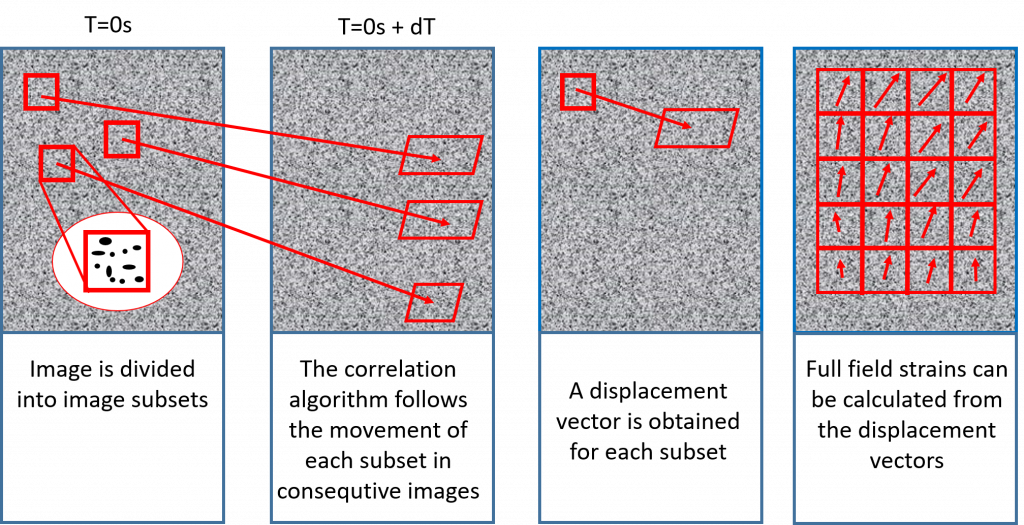

- The measured surface needs to have enough optical contrast. This can be either natural contrast or the surface can be painted or otherwise treated to produce a random pattern.

- Calibration images are obtained from a well-known calibration target. These images are used to calibrate a pin-hole camera model, or possibly a more complicated model, that connects the camera coordinates (pixels) to the sample coordinates.

- The image is divided into small subsets, and the movement of the subsets is tracked from one image to the next.

- The displacement vectors are obtained for each subset and for each image resulting in a full field displacements and strains over the target surface.

- The results can be processed in many different ways, and various data can be extracted from the displacement and strain data.

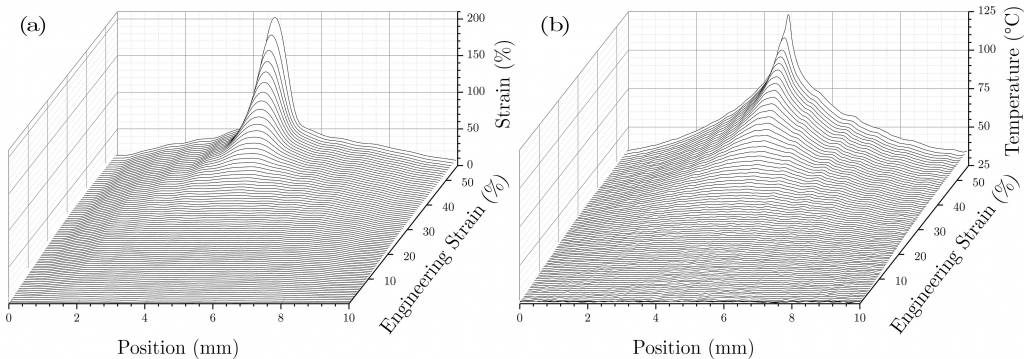

We use DIC for variety of applications, where we track either displacements or strains of a target during a test. This method is very useful, for example, when studying strain localizations, necking during tensile test, and fracture of a specimen. These all are local phenomena, which would be rather difficult to study with a simple strain gage or extensometer. Recently we have also used the DIC together with infrared imaging, and calibrated the two image modalities to the same coordinate system. This allows measurement of both temperature and deformation of the sample at a very high spatial resolution. This is a very powerful tool for complete analysis of thermomechanical behavior of the material.

DIC is also very useful for comparing experimental and simulation results. It may be easy to develop a model that predicts an average strain or average forces, but the detailed comparison of the full field strains requires a very good model.

We are always developing our skills and know-how of Digital Image Correlation, and we are looking for new applications of this measurement method. We have developed a measurement tool for analyzing the deformation and movements of the human heart during open-heart surgery. A following video demonstrates our innovation, for which we also have an EPO and US patents pending for approval.

Our experimental capabilities

We are currently using a commercial DAVIS10 system from LaVision.

Low rate system

- 2 cameras: Imager E-Lite 5MPix CCD cameras.

- 12bit images, 12 fps at full resolution

- Lightweight mounting system for easy access of cameras and lights

- Pulsed LED Lights. Operated directly from Davis software

- Additional Zeiss Discovery v.8 stereo microscope with horizontal mounting system

High rate system

- 2 Cameras: Photron SA-X2

- 12 bit images, 1MPix maximum resolution. 12.500 fps at max.res. Higher fps at reduced resolution,e.g. 200kHz @ 256*152

- 16GB of internal memory, recording time around 0.7 to 10 seconds depending on the resolution and fps

- A rigid mounting system for the cameras and lights

- High speed trigger unit

- DecoCool high power lights

- Additional Zeiss Discovery v.8 stereo microscope with horizontal mounting system

IR:

The TELOPS Fast IR-1500 M2K high speed IR camera offers high-speed thermal imaging with high temporal resolution. Therefore, it is ideal to analyse dynamic events.

- Full size image of 320 × 256 pixels up to 2000 frames per second. At higher speeds, the size of the image decreases.

- Maximum frame rate of 90 kHz with an image of 64 × 4 pixels.

- 4-position filter wheel that allows imaging at a broad range of temperatures up to 1500 °C.

- Several optical configurations available to cover various field of views and working distances

- Spectral range of 1.5 to 5.5 µm

- Can be used simultaneously with optical cameras and Digital Image Correlation

Simultaneous high speed DIC and IR analysis

The DIC and IR imaging can be carried out simultaneously so that for each DIC image there is a corresponding IR image. Or alternatively the DIC images can be aquired at a higher frequency so that every Nnt image is acquired simultaneously. At low imaging speeds this is quite challenging, but at high rate this is technically a very complex and difficult test. The temporal synchronization together with spatial matching of the two images allows extracting both temperature and strain information on any pixel location of the specimen. We have developed spatial calibration methods that allow spatial synchronization of the images by first calculating the full field displacements from the DIC analysis and applying those vector displacements on the infrared image. This allows careful evaluation of, for example, adiabatic heating in strain localizations, shear bands, necking etc.

Other high speed video systems

Memrecam fx K5

Memrecam fx K5 provides ultra high light sensitivity, ultra high speed and mega pixel

resolution. It is a fully self-contained, digital, high-speed video system that records brilliant

colour images or crisp monochrome images. The robust Memrecam fx K5 is perfect for any

high-speed imaging application being performed in a hazardous environment. The Memrecam

fx digital cameras allow the user to record mega pixel images for more than 10 seconds at

1000 fps and over one minute at reduced resolution.

- Megapixel Sensor

- Frame rates up to 168,000fps

- Ultra-High Light Sensitivity— ISO 5,000 Colour & 32,000 Monochrome

- 1280 x 1024 resolution

- Gigabit Ethernet control 100m+ or 100baseT Ethernet operation.

Cordin 535-16

Cordin model 535-16 is a High Resolution Rotating Mirror CCD Framing Camera System. This system use a complex optical system centered on a multi-faceted mirror that spins at very high speeds. This action distributes the image to individual CCD channels which record the frames. This approach yields the best image quality available in ultra-high speed applications.

- Number of Frames: 16

- Maximum framing Rate: 1 million

- Minimum Interframe time: 1.0 us

- Minimum Exposure Time: 800 ns

- Front Optics: Single objective lens system (no parallax)

- Objective Lens: Nikon F-mount

- Resolution: 1000 x 1000 pixels

- Pixel size: 7.4 x 7.4 mm

- Dynamic Range: 10 bit

- Device Type Full resolution progressive scan