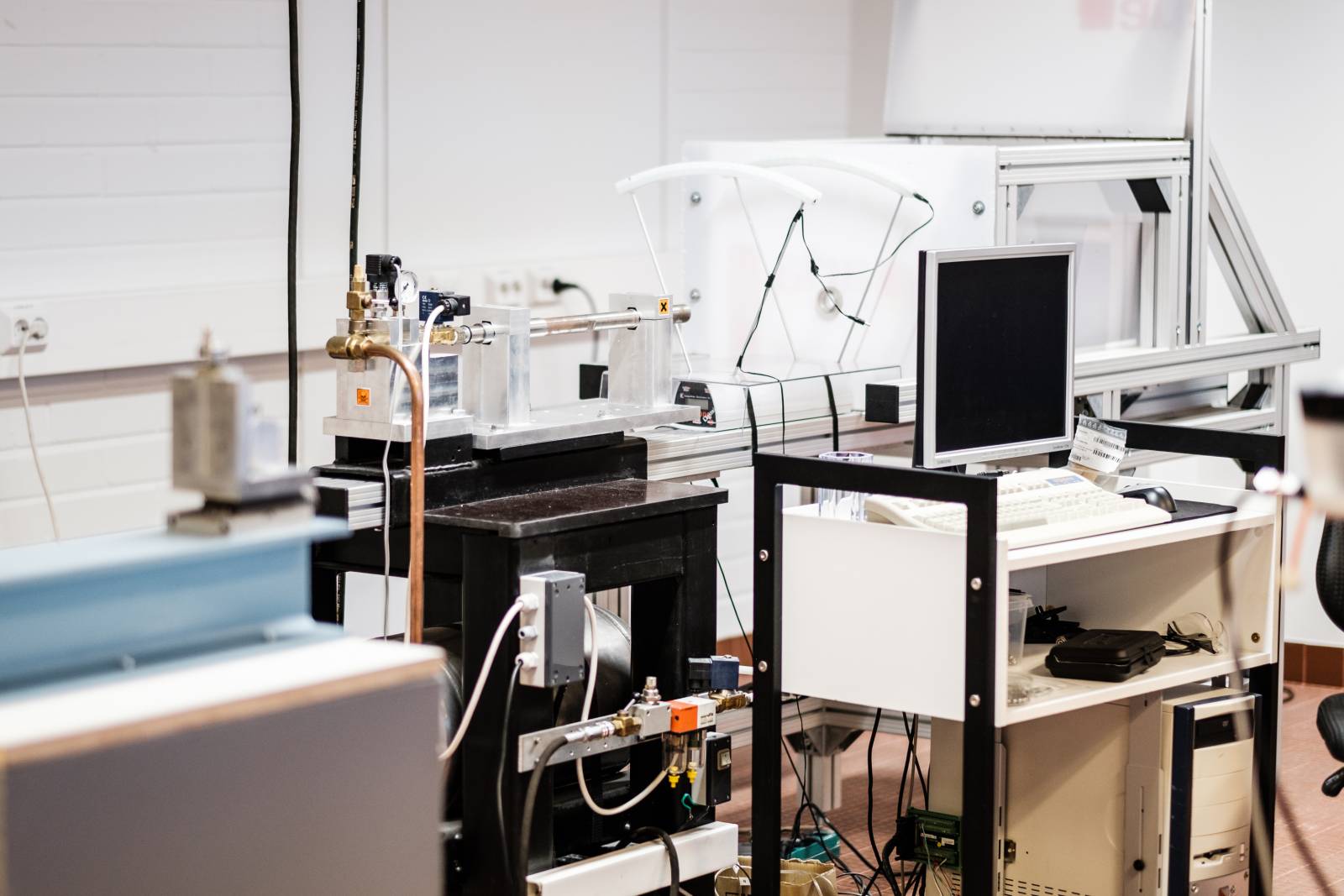

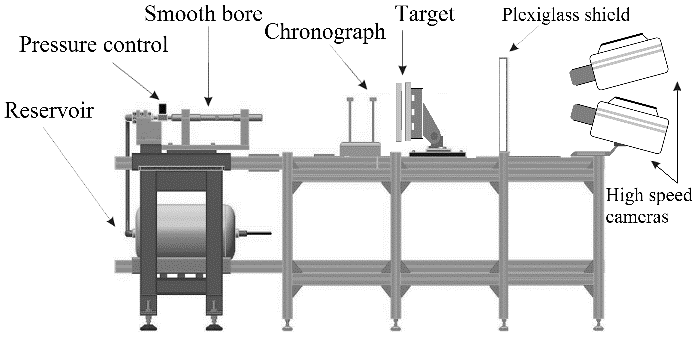

THe HVPI was originally developed for experimental research of high speed impacts of small particles. This device simply accelerates small balls or cylinders to high velocities and impacts them to the sample target at a preset angle. The device was originally developed for model verification purposes, but has been also used to carry out various impact tests including High Temperature Taylor Experiments, and high-low temperature impacts. The HVPI is a very versatile device as it allows imaging of the impacts from the front, size, and back side of the specimen. Using two high speed cameras on the back side of the specimen allows recording of 3D in-plane displacements and strains on the sample as well as the out of plane displacement (not the strain). A schematic picture of the device is shown below, as well as several high speed videos of actual tests.

Above you can see a high speed camera video of a 5mm diameter bearing ball impacting a steel target at a preset angle. A good overview and technical descriptions of low temperature impact testing can be found in this recent open-access publication:

Valtonen et al. Impact Wear and Mechanical Behavior of Steels in Subzero Conditions. Tribology International vol. 129 (2019).