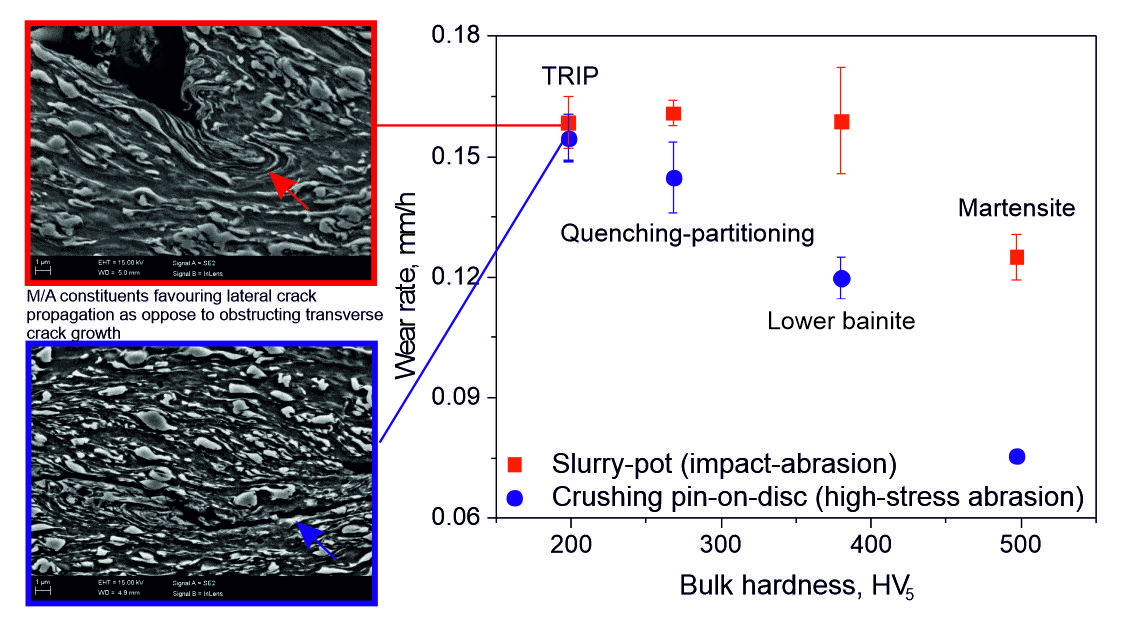

This work investigates steels for mining wear applications involving abrasive and impact-abrasive conditions. The study comprises four low carbon steels with a range of hardness-toughness combinations: a commercial grade martensitic steel, the same steel heat treated to lower bainite, a commercial TRIP steel (tensile strength grade 700 MPa), and a quenching-partitioning (QP) steel. The steels were subjected to crushing pin-on-disc (CPOD) and slurry-pot wear tests, offering reasonably high-stress abrasive and impact-abrasive conditions, respectively. The results showed that the best performer in both studied wear conditions is the martensitic steel due to its higher initial hardness. Nevertheless, the performance benefit of this steel was of lesser magnitude in the slurry-pot than in the CPOD tests. On the other hand, the TRIP steel showed poor ranking in the CPOD tests but outperformed the QP and lower bainite steels in the slurry-pot tests. Detailed surface and subsurface wear damage investigations were conducted to study the wear responses of the microstructural constituents of the steels to explain their wear behavior in different wear conditions.

Gourab Saha, Kati Valtonen, Ari Saastamoinen, Pasi Peura, Veli-Tapani Kuokkala,Impact-abrasive and abrasive wear behavior of low carbon steels with a range of hardness-toughness properties, Wear,Volumes 450–451, https://doi.org/10.1016/j.wear.2020.203263

The article is available open access with this link until May 7, 2020 https://authors.elsevier.com/a/1alJc_%7Eq2Nqe3