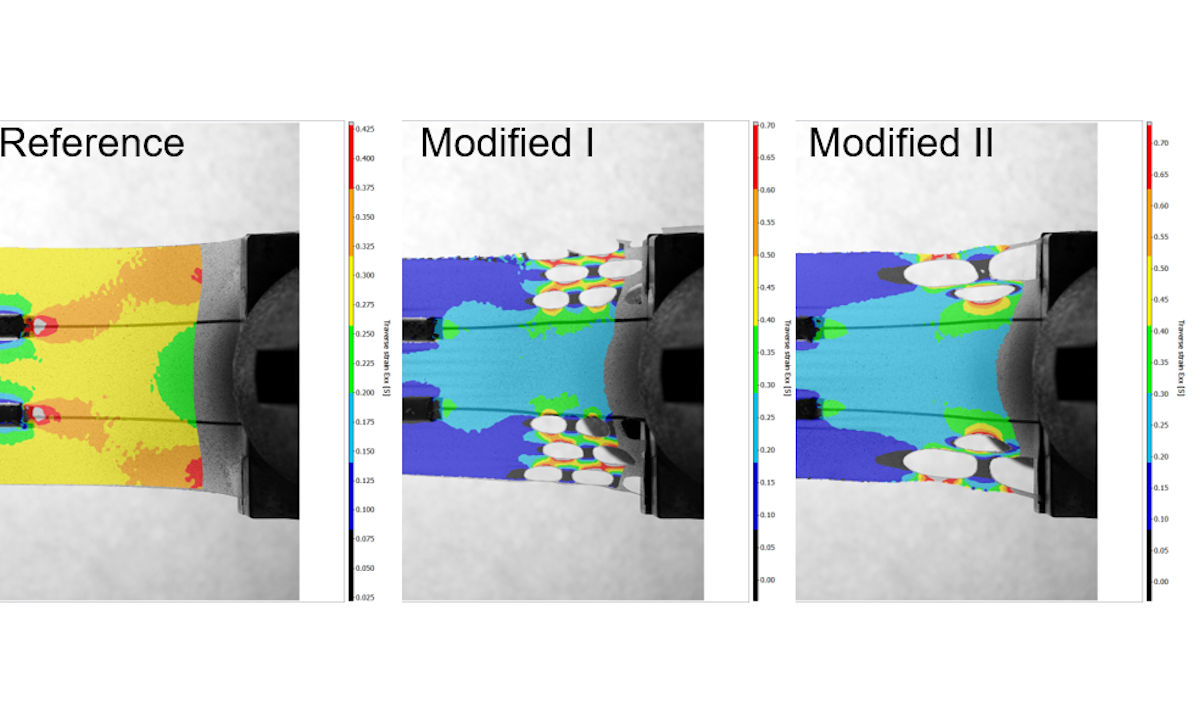

A typical stretchable application consists of small-sized, rigid IC-chips and passive components interconnected by conductive tracks on soft substrates. The early failure of such devices initiates from the rigid-soft interface due to the accumulation of stress. Therefore, special attention is needed to reduce the strain concentration at the interface. In this paper, stretchable interconnects were fabricated using a screen-printing method and surface mounted devices (SMDs) were bonded using an isotropic conductive adhesive. By partially removing material from the substrate in areas a little way from the rigid components, the stiffness is locally reduced, and this leads to an increase in the local stiffness around the SMDs and hence shields the soft-rigid interface against the stress. Materials can be removed by two different patterns. A finite element analysis and experimental data show 11%–19% improvements in single pull-up tests for the modified samples. This approach makes the electromechanical behaviour independent of encapsulation properties.

Improvements in the electromechanical properties of stretchable interconnects by locally tuning the stiffness

Recent advances in materials science and structural design have changed electronic applications from being bulky and rigid objects to small and soft products that have emerged for a wide range of applications, especially human-related products for which mechanical adoption is the key requirement.