Current Collectors for Low Resistance Aqueous Flexible Printed Supercapacitors

Maedeh Arvani, Jari Keskinen, Donald Lupo, Mari Honkanen

In this paper we propose various current collector alternatives to be used in flexible supercapacitors with aqueous electrolyte when low equivalent series resistance (ESR) is required. The current collector material should be corrosion resistant when in contact with the saline electrolyte. Simultaneously it should have high electrical conductivity. In addition, environmental and cost aspects must be taken into account. We report supercapacitors with current collectors made of two different thicknesses of graphite foil (25 µm and 150 µm) and aluminium coated with graphite inks. These disposable and non-toxic supercapacitors show remarkable improvements in ESR compared with values obtained for similar components with current collectors made of graphite ink. When graphite foil or aluminium is used as current collector, the ESR can be decreased by more than 80 % compared to using graphite ink alone. Supercapacitors using a dense graphite protective layer on top of aluminium showed no sign of corrosion and their performance was not significantly reduced after ageing for 950 days. With graphite foils, comparable ESR values can be obtained as with aluminium. The graphite foil is an interesting alternative if metal materials should be avoided, e.g. to facilitate incineration of the supercapacitors together with regular household waste. Especially with non-porous graphite foil, we obtained properties suitable for practical applications.

Journal of Energy Storage 29 (2020) 101384

Additive Manufacturing of Monolithic Supercapacitors with Biopolymer Separator

Maedeh Arvani, Jari Keskinen, Anna Railanmaa, Sanna Siljander, Tomas Björkqvist, Sampo Tuukkanen, Donald Lupo

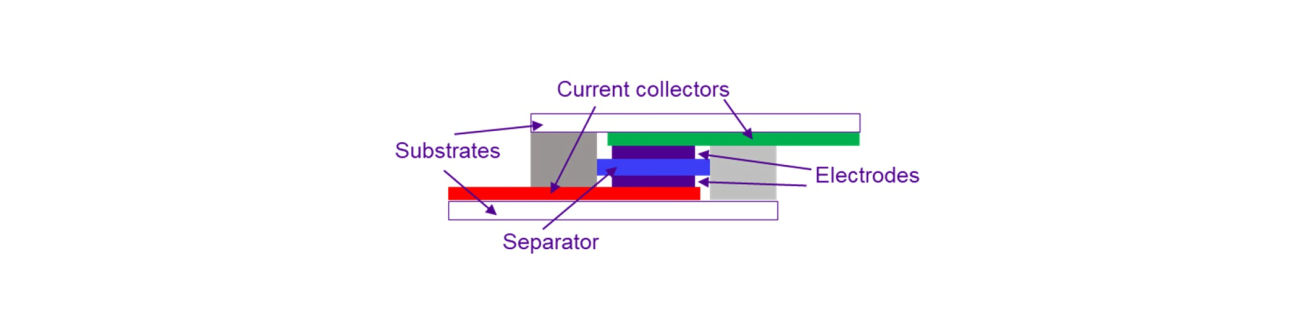

In this paper, additive layer-by-layer fabrication of a fully screen printed monolithic supercapacitor exhibiting performance comparable with supercapacitors prepared using lamination is reported. A novel separator material improves the performance of the monolithic supercapacitor, is easily applicable using scalable processes such as screen and stencil printing, and is based on sustainable biomaterials. The additive monolithic manufacturing offers advantages for system integration and avoids the need of an additional alignment step as needed in the fabrication of laminated supercapacitors. Previously, the monolithically fabricated supercapacitors showed higher equivalent series resistance (ESR) and leakage current than the laminated ones. By using microfibrillated cellulose (MFC) and chitosan as separator materials ESR and leakage current were decreased. These disposable and non-toxic aqueous electrolyte supercapacitors are optimized for autonomous sensor systems, for example in Internet-of-Things (IoT) applications, with capacitance of 200–300 mF and ESR of about 10 Ω. The new composite separator material consisting of MFC and chitosan has good adhesion on the electrodes and the substrate, is easy to apply using printing and coating processes, and does not diffuse into the porous electrode.

J Appl Electrochem 50, 689–697 (2020)

Flexible Energy Supply for Distributed Electronics Powered by Organic Solar Cell and Printed Supercapacitor

M. Arvani, J. Keskinen, S. Mansfeld, A. Railanmaa, C. Rokaya, A. Hiltunen, P. Vivo, D. Lupo

In this work we report a flexible energy supply unit made by printing flexible disposable aqueous supercapacitor modules onto a light harvester. In order to demonstrate simpler and more scalable manufacturing processes, we printed the supercapacitors monolithically instead of laminating electrodes face-to-face and integrated the series connections into the fabrication process. The supercapacitor modules were printed onto the backside of the Organic Photovoltaic (OPV) modules to combine energy harvesting and storage module for harvesting light under normal indoor conditions, storing it in a supercapacitor module, and thus offering power for low power IoT devices.