Fu et al. have published an interesting article in Microelectronics Reliability, 2021, 119, 114067.

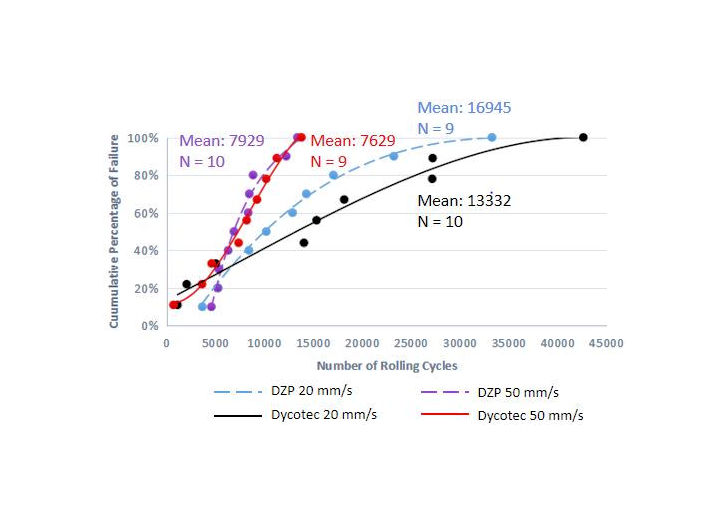

In this study, bending reliability of the surface mounted devices (SMD) attached using isotropic conductive adhesive (ICAs) on screen printed stretchable devices polyurethane substrate are investigated. The performance of polyurethane and polyurethane-acrylic ICAs and the impact of rolling speed are studied. The rolling test was performed using the customized automatic rolling test device. It was found that the polyurethane-acrylic blend gives poorer adhesion with the silver conductor and very high cohesive force. The polyurethane resin brings adhesive high adhesive force with the silver conductive layer while lower adhesion with the Tin surface of the SMD, and it exhibited poorer cohesive force. The resistance of all samples experienced a steady and slow increase period before it accelerated to failure. During the slow and steady increase phase, the increased resistance was mainly from the conductive layer, whereas during the dramatic increase phase, it was mainly from the ICA connected area. The increased rolling speed had accelerated the resistance evolution process and lowered the samples’ reliability severely. It also lowered the adhesion of the polyurethane-acrylic blend with the ink layer and lowered cohesive force of polyurethane ICA.