Today, increasing part of added value for new technical solutions comes from digitalization and advanced automation. Using Big data and cloud analytics, machines can be made more reliable, more energy efficient and the operation can be optimized. In EDGE project, the target is to transfer the capabilities of Big data and cloud processing to the Edge, enabling real-time safety-critical operation, regardless of communication availability and at the same time minimising data transfer costs.

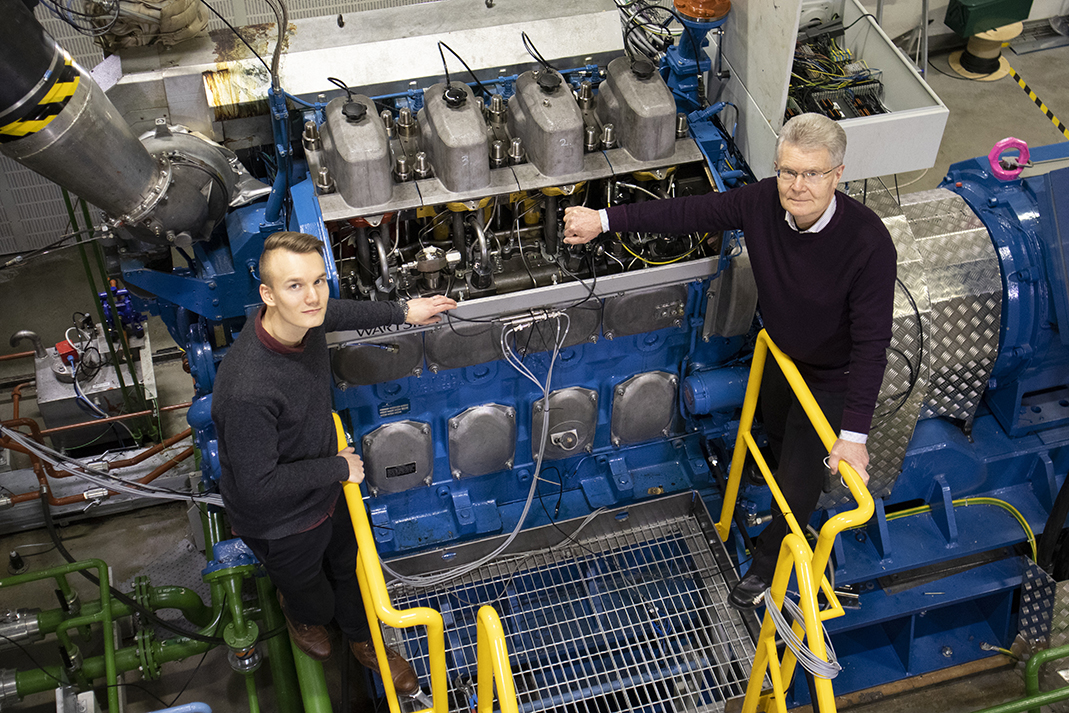

The developed solutions and methods are utilised for the needs of machine industry. Analytics solutions enable smart diagnostics, predictive maintenance and optimisation of operation. The solutions are verified and validated using demonstrators (ship engines, mobile work machine, harbor crane, substation switching devices) and data collected from these systems.

EDGE Final Report

EDGE Final Report – 1 Project Introduction

EDGE Final Report – 2 Unmanned engine room

EDGE Final Report – 3 Leakage detection in engine room

EDGE Final Report – 4 Acoustic data analysis

EDGE Final Report – 5 Mobile machine operator profiling

EDGE Final Report – 6 Harbor crane data analysis

EDGE Final Report – 7 Presentation of Edge system architecture

EDGE Final Report – 8 Dissemination and cooperation model

Prof. Seppo Niemi and project researcher Lauri Nyystilä in VEBIC engine test laboratory. VEBIC demonstrator results are presented in EDGE Final Report parts 2 and 3.