Calculation analyses to study mould and microbe growth can be performed using the Finnish mould growth model developed by the Technical Research Centre of Finland (VTT) and Tampere University of Technology. The model is based on the original mould growth model for wood, which was created by VTT and PhD Hannu Viitanen. With the Finnish mould growth model, mould and microbe growth can be evaluated on different materials in changing temperature and moisture conditions. The Finnish mould growth model is currently the most advanced tool for assessing mould growth in the world. The file for the model can be found through the link below.

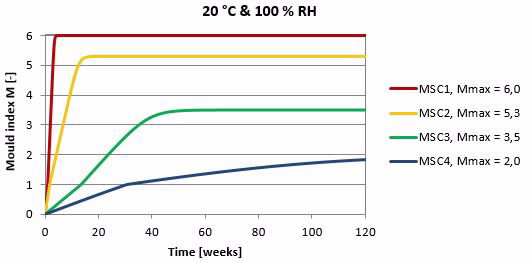

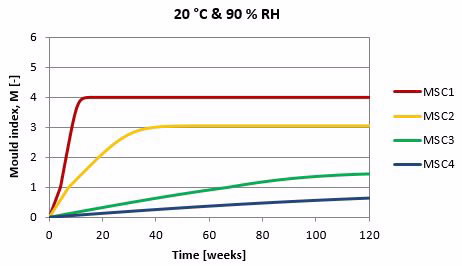

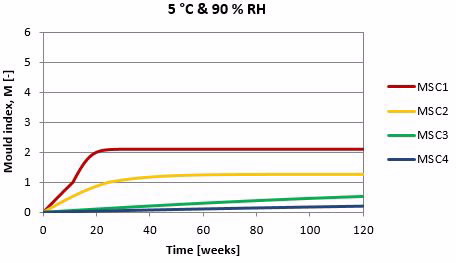

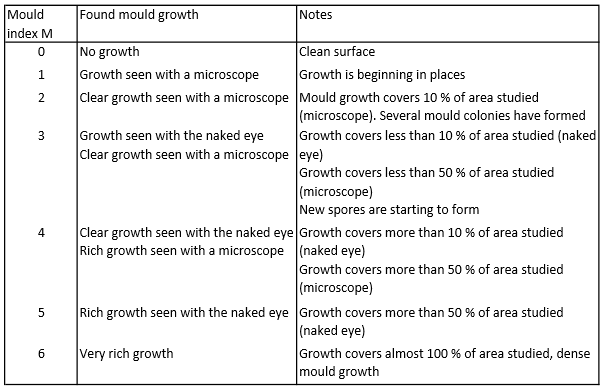

The mould risk is described with a mould index M, which ranges between 0 and 6, and depicts the increasing amount of mould on the surface. The mould risk is calculated from hourly temperature and relative humidity values. The model also takes into account mould decline when conditions are not favourable for mould growth (too cold or too dry). The mould index only describes the general growth of mould on materials and therefore says nothing about the mould types, so it can’t be used to evaluate how hazardous the mould would be.

The Finnish mould growth model includes the next characteristic features which were not included in the original mould growth model by VTT:

- The mould risk (mould index) can be calculated for all construction materials and structures for which the sensitivity class is known.

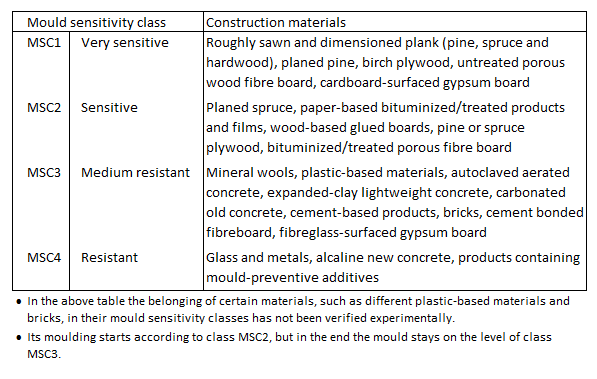

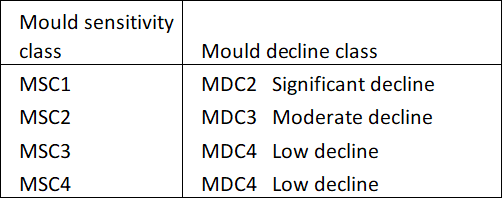

- The differences in construction materials’ mould growth sensitivities are taken into account by dividing them into four sensitivity classes and four decline classes. All mould sensitivity classes and mould decline classes have their own associated factors for calculating mould index.

- The effects of surface type, surface coating and contact to other materials can be taken into account by using appropriate mould growth sensitivity and mould decline classes.

- The descriptions of mould index classes 3 and 4 contain the high mould coverage only visible with a microscope.

- Laboratory tests were used to verify the applicability of the model for different materials, structures and material interfaces, as well as for unfavourable conditions (too cold or too dry).

- Using a calculation time step of one hour created the best correlation between calculated and measured values.

Moulding properties of materials can be estimated based on the beginning of mould growth, the maximum amount of mould, and the mould decline. It can usually be stated that the faster the mould growth begins, the higher the mould maximum can be and the faster it will decline in unfavourable conditions. Autoclaved aerated concrete is an exception.

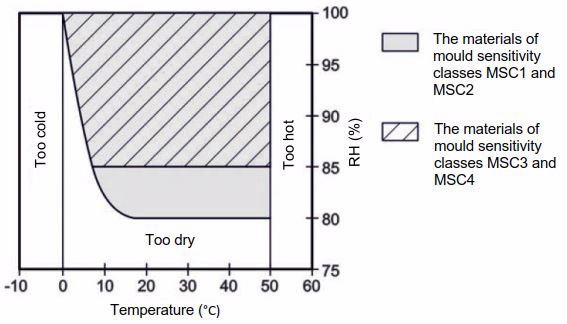

Temperature and relative humidity both affect the growth rate and maximum value of the mould index. Mould growth stops and decline starts when the temperature falls under 0 °C or rises above 50 °C or relative humidity falls under 80/85 % RH (depends on the mould sensitivity class of the material).

The pictures below illustrate the effect of different mould sensitivity classes on the mould growth rate and maximum mould index in constant conditions.