The ECOSAFE-project, run by the building physics research group, is in progress at Tampere University. The aim is to determine the performance of plastic-free and non-toxic structures insulated with sawdust and cutter shavings in current and future climate conditions. The focus of the project are the building physical properties of sawdust-based insulation materials and the moisture performance of structures insulated with such materials, compared to common mineral wool and cellulose insulation. Based on the results, recommendations and structural concepts will be drafted for executing moisture safe exterior walls, roofs and base floors insulated sawdust and cutter shavings in one-family houses and larger timber buildings. In addition, the U-value requirements with which the carbon footprint over the lifetime of a sawdust-based structure is below that of the structures that fulfill the current energy efficiency regulations is determined, and recommendations are drafted for the reference values of the U-values of these structures.

Due to climate change the significance of timber construction has increased, since the carbon footprint caused by it is small. On the other hand, the challenges of timber construction are moisture sensitive materials and the added moisture loads caused by climate change, which is why special attention must be paid to the design and construction of structures. As a result of the current energy efficiency regulations, timber structures are designed as layered structures, which are better at insulating heat than one-layered log structures, but more prone to moisture damage. It is possible to improve the moisture safety of a timber structure significantly by increasing the structure’s moisture capacity, which decreases the risk of moisture condensing and microbes growing inside the structure. This can be achieved by changing the mineral- or plastic-based insulation of a timber structure to a sawdust- or cutter shaving-based insulation. This way the fault tolerance of a layered timber structure can be improved significantly, since the large moisture capacity of the insulation can eliminate the harmful effects of occasional small leaks.

The drawback of sawdust-based insulation is lower thermal resistance compared to other used insulation materials. On the other hand, this improves the moisture performance of structures, since it allows the temperature of the outer layers to rise. The weaker energy efficiency can be compensated by analyzing the total environmental impact, since, because of the smaller carbon footprint, the U-value doesn’t have to be as good as it does for efficient industrial insulation materials. Additionally, sawdust and cutter shavings are surplus products of the sawmill industry, so using them in structures would decrease material wastage.

During the project the performance of structures insulated with sawdust is studied both computationally and experimentally. The computational analyses of structures are done using the analysis method for moisture performance, where structures are analyzed in critical indoor and outdoor climate conditions in current and future climates. The method was developed by the building physics research group of Tampere University. The performance of the structures is assessed using the Finnish mould growth model, developed by the Technical Research Centre of Finland (VTT) and Tampere University, which can be used to determine the mould risk in different points of the structure. This method of analysis is currently one of the most advanced methods in the world, so the results will be scientifically high quality.

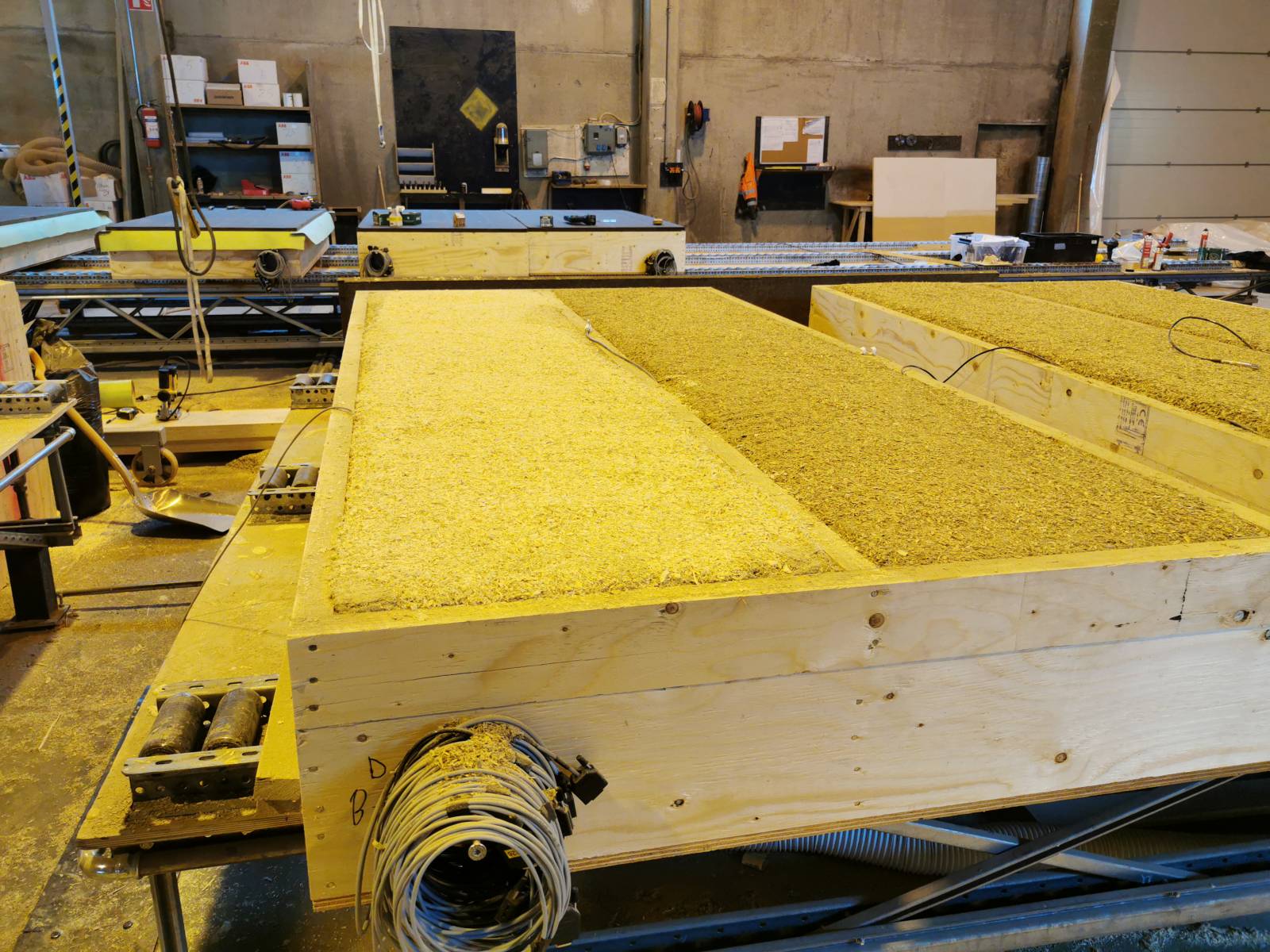

The hygrothermal performance of walls with sawdust insulation is also studied experimentally. This way the computational and experimental results can be compared, which improves the reliability of the results. After all, high-level building physical research requires both computational and experimental analysis nowadays. New research equipment and test buildings are available for the experimental studies, which will improve the reliability of the results.

The responsible leader of the project is Professor Juha Vinha (juha.vinha@tuni.fi) and the project manager is Eero Tuominen (eero.tuominen@tuni.fi).